We all know that flanges are parts of shafts and shafts that are connected to each other and used for connecting the ends of pipelines. The editor wants to ask, what are the benefits of flanges? There are many benefits to flanges! For example, flange connections are detachable connections, which are more convenient and hassle free. How to make centrifugal flanges? Editor and everyone's science popularization one or two.

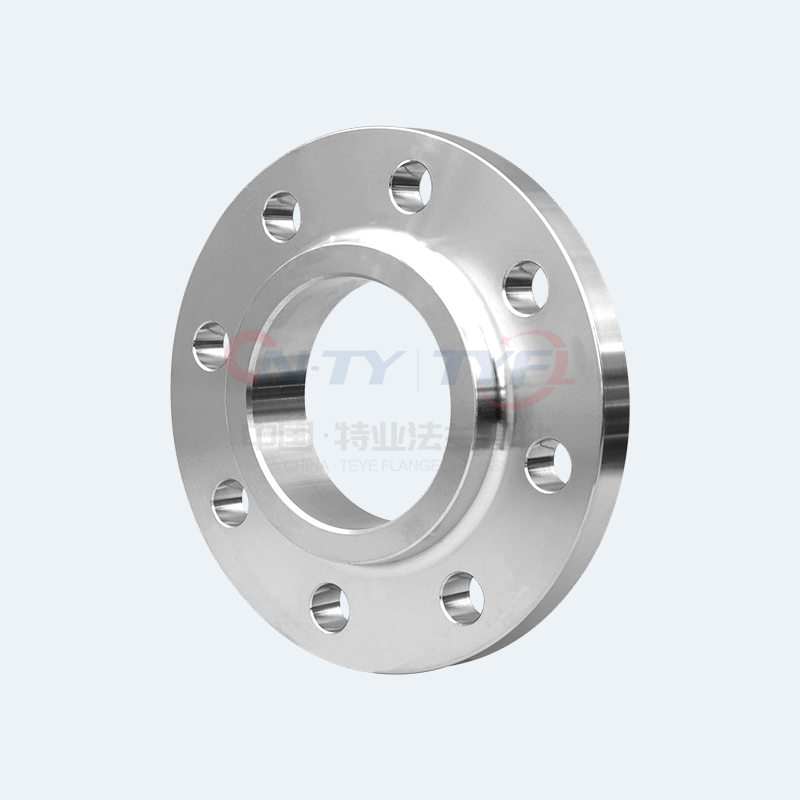

Firstly, everyone needs to understand the types and connections of some flanges, right? Pipeline flange refers to the flange used for pipeline installation. It is used on equipment to refer to the inlet and outlet flanges of the equipment. There are holes on the flange, and bolts make the two flanges tightly connected. The flange is sealed with a gasket. Flange threaded connection (threaded connection) flange, welding flange, and clamping flange. Use flanges in pairs. Low pressure pipes can be used together with wire welded flanges. How about enduring pressure?

Welding flanges are used for pressures above 4 kilograms. The gasket is placed between two flanges and then secured with bolts. Use different bolts for different flange thicknesses under different pressures. Pumps and valves also have flange connections. The connection of ventilation ducts can be referred to as "flange components". However, this connection is only a part of the equipment, such as the connection between the flange and the water pump, known as the "flange component" of the pump. We can also refer to smaller valves as "flange components".

Due to the different production processes, it can also be understood that there are differences between cast flanges. Centrifugal flanges belong to the production of flanges using precision casting method. This type of casting has a much thinner structure and greatly improved texture compared to ordinary sand casting. And we also found that there are few issues such as tissue loosening, pores, and trachoma.

Firstly, we need to be familiar with how centrifugal flanges are produced and manufactured through centrifugal casting. The product is processed through the following process steps:

1、Introduce the selected raw steel into the medium frequency electric furnace. This causes the temperature of the molten steel to reach over 1000 degrees Celsius;

2、Preheat the metal mold to 800 to 900 degrees Celsius to maintain a constant temperature;

3、Start the centrifuge and inject the molten steel from step 1 into the preheated metal mold in step 2;

4、Casting naturally cools to 800 to 900 degrees Celsius for 1-10 minutes;

5、Finally, cool with water and wait for the flange to reach room temperature before demolding to remove the casting.